The Core Principles Behind the Three Imaging Technologies

DLP projection technology: A micro-mirror–based reflective system

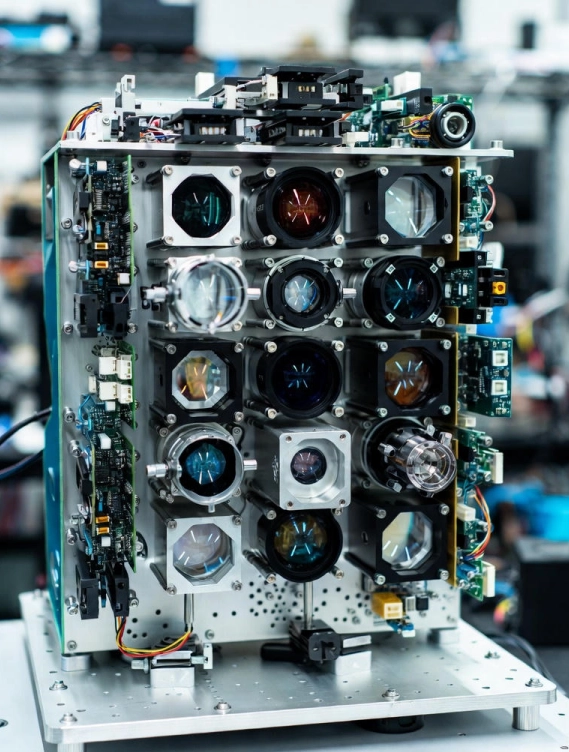

At the heart of DLP projection technology lies the Digital Micromirror Device (DMD), an optical semiconductor containing thousands — or even millions — of individually tilting micro-mirrors. Texas Instruments has published extensive documentation on DMD switching behavior, showing that each micro-mirror can toggle between two states at several kilohertz, reflecting light either toward the projection lens or away from it (source: https://www.ti.com/lit/wp/dlpa067/dlpa067.pdf). This binary reflection behavior creates grayscale levels via pulse-width modulation, and color is formed through sequential color wheel operation or multi-primary LED/laser light sources. Because the micro-mirrors in DLP projection technology are made from aluminum and anchored via torsion hinges, they exhibit exceptional resistance to heat and UV exposure. As a result, degradation over time is minimal. Moreover, the reflective nature of the system keeps optical path contamination low, as no liquid crystal layers are present inside the imaging chip. This structural simplicity contributes significantly to long-term reliability — a property corporate buyers value. Another major advantage of DLP projection technology lies in its fill factor (typically above 90%), meaning the image appears smoother at normal viewing distances. High fill factor reduces the screen-door effect, a common issue in LCD-based projectors.

LCD technology: A transmissive liquid-crystal modulation system

LCD projectors, in contrast, rely on light passing through three liquid-crystal panels, each corresponding to red, green, and blue channels. These transmissive panels modulate brightness via voltage-controlled liquid-crystal alignment. Although LCD systems often produce vivid color saturation due to continuous color output (rather than sequential color), they have inherent weaknesses. Liquid crystals degrade when exposed to heat and UV radiation, leading to color shifting over time. This phenomenon, frequently called “color decay” or “panel burn-in,” has been documented in multiple display engineering studies (example reference: https://opg.optica.org/ao/fulltext.cfm?uri=ao-43-12-2586&id=60810). Moreover, LCD panels must remain perfectly aligned optically. Even slight thermal warping can cause color convergence issues, creating visible color fringing. While modern systems incorporate compensation mechanisms, the fundamental physics of transmissive imaging makes LCD inherently more sensitive to contamination (dust spots), moisture, and thermal stress than DLP projection technology.LCoS: A reflective liquid-crystal architecture

LCoS attempts to merge the strengths of DLP and LCD by using a reflective liquid-crystal layer on top of a silicon backplane. Instead of transmitting light, LCoS modulates reflected light — allowing high resolution and excellent smoothness. Imaging scientists frequently note that LCoS systems can achieve extremely high fill factors and low pixel visibility (see IEEE Journal of Display Technology, https://ieeexplore.ieee.org/document/7785757). However, because LCoS still relies on liquid-crystal modulation, it inherits several LCD weaknesses, including susceptibility to panel contamination, organic material degradation, and thermal instability. LCoS systems can deliver outstanding static images but are not always ideal for environments with long daily operating hours or high ambient heat.Image Quality: Sharpness, Motion Handling, and Color Accuracy

Sharpness: Micro-mirror geometry gives DLP projection technology a structural advantage

Sharpness is defined by both the inherent optical engine design and the stability of pixel boundaries. In DLP projection technology, each micro-mirror acts like a perfectly defined pixel, producing crisp edges and high MTF values. Because mirrors tilt rather than deform, their modulation remains consistent throughout the projector’s lifespan. LCD, however, introduces diffusion due to liquid-crystal layers, and pixel boundaries may appear softer. LCoS improves pixel uniformity but still cannot match the micro-mirror precision produced by DLP projection technology.Motion: DLP projection technology delivers superior temporal response

Micro-mirrors switch states at extremely high frequencies, making DLP projection technology uniquely suited for:- Fast-motion video

- Data visualization

- Engineering simulations

- Rapid transitions in UI environments

Color reproduction: LCD excels, but DLP projection technology maintains consistency longer

LCD’s continuous color modulation typically produces rich, saturated imagery, making it visually appealing in low-contrast environments. LCoS performs similarly but with better uniformity. However, DLP projection technology maintains color stability longer because micro-mirrors do not degrade or discolor. Over a multi-year lifecycle, DLP color consistency tends to outperform LCD and LCoS, especially in high-temperature or dusty environments.Brightness, Contrast, and Optical Efficiency

Brightness stability: why DLP projection technology resists light-path degradation

Brightness performance involves more than simply lamp or laser output; it depends heavily on how efficiently the imaging engine preserves that light as it moves through the optical path. One of the reasons DLP projection technology maintains strong brightness stability over time is the rugged nature of its micro-mirror array, which neither absorbs light nor suffers chemical deterioration. The mirrors continue reflecting photons with nearly the same efficiency even after years of thermal cycles, dust exposure, and long-duration corporate usage. In contrast, LCD panels allow light to pass directly through them, and their polarizers gradually deteriorate under heat. Multiple optical engineering papers have documented how LCD polarizers experience molecular breakdown that reduces transmittance after extended operation under high-intensity light sources (Ref: Optical Engineering Journal – “Thermal Deterioration Characteristics of Polarizers in High-Luminance Projectors” https://doi.org/10.1117/1.OE.52.7.073102). This degradation slowly reduces the projector’s brightness and can create a yellow or brown tint — a phenomenon widely recognized in commercial usage environments. LCoS performs better than LCD in this category because it is reflective, but the liquid-crystal layer still interacts with high-intensity light, and any contamination on the panel can lower reflectivity. Only DLP projection technology, with its all-metal micro-mirror design, consistently avoids this issue, maintaining a cleaner optical path over long service cycles.Contrast ratio: reflective systems outperform transmissive ones

Corporate environments often present mixed lighting conditions. Meeting rooms may contain sunlight from windows, LED lighting, and large display walls, so contrast ratio becomes a crucial metric. Reflective systems — both DLP projection technology and LCoS — inherently achieve deeper blacks because they physically divert light away rather than partially suppressing it. LCD panels, being transmissive, cannot completely block light, leading to elevated black levels. LCoS often achieves the highest native contrast, but DLP projection technology achieves superior dynamic contrast in practical conditions due to faster modulation and better resistance to panel aging.Optical efficiency: fewer layers, fewer losses

Because DLP projection technology uses a single reflective surface with minimal optical layers, its efficiency remains high across time. LCD contains multiple layers:- glass substrates

- alignment layers

- liquid crystal compounds

- color filters

- polarizers

Reliability and Long-Term Stability in Business Environments

Thermal resilience: DLP projection technology tolerates heat better than LCD or LCoS

Corporate installations — especially ceiling-mounted systems in small rooms — often expose projectors to continuous heat. Micro-mirrors are made of aluminum and silicon, both of which exhibit predictable, stable behavior under thermal cycling. This makes DLP projection technology particularly resilient in:- small conference rooms with poor ventilation

- classrooms with long operating schedules

- enterprise environments that require 8–12 hours of daily use

- image retention

- color drift

- uneven brightness

- stuck pixels

Dust resistance: sealed micro-mirror architecture protects image quality

Dust intrusion is one of the most common causes of projector service calls. Dust on an LCD panel produces permanent dark spots; dust on an LCoS panel produces bright or muddy artifacts. However, DLP projection technology uses a hermetically sealed DMD chip, preventing dust from landing on the active imaging surface. This design choice is critical for corporate buyers because dust-related image defects cannot be cleaned easily in non-DLP systems; they often require panel replacement.Mechanical endurance: mirror hinges last millions of cycles

Each micro-mirror in DLP projection technology hinges back and forth at tremendous speeds — measured in tens of thousands of movements per second. Despite this, the mirror hinges experience extremely low mechanical wear due to their microscopic mass and materials science design. Semiconductor reliability studies indicate DMD mirrors routinely exceed hundreds of billions of switching cycles without functional degradation (Reference: TI Whitepaper – DMD Reliability Fundamentals https://www.ti.com/lit/an/dlpa024a/dlpa024a.pdf). LCD and LCoS systems lack moving parts internally, but their organic materials degrade chemically, not mechanically. In effect, DLP projection technology trades chemical degradation for mechanical endurance — and mechanical endurance wins in longevity.Resolution, Pixel Structure, and Image Smoothness

Pixel structure: DLP projection technology produces higher fill factors

The fill factor — the percentage of pixel area that emits useful light — influences how smooth an image appears. DLP projection technology typically achieves fill factors above 90%, meaning edges look clean and fine text appears sharp even at low distances. LCD panels often exhibit noticeable pixel boundaries (“screen door effect”), especially in lower-resolution models. LCoS achieves high fill factor too, but because it uses liquid-crystal layers, uniformity can shift over years of use.Resolution scalability

DLP chips scale efficiently from WXGA to 4K due to the regularity of micro-mirror arrays. LCoS handles high resolution well but sometimes struggles with heat dissipation at 4K resolutions. LCD systems tend to be more efficient at lower resolutions but face challenges scaling to extremely high pixel densities without increasing artifacts caused by panel alignment.Color Performance: Static Accuracy vs. Long-Term Stability

LCD advantage: strong initial color saturation

LCD projectors often produce images with high saturation and vivid colors, which can be visually pleasing in controlled lighting environments. This comes from RGB channels being projected simultaneously rather than sequentially.LCoS: excellent color uniformity

LCoS typically wins in uniformity across the screen because liquid crystals modulate reflected light evenly. In photography or medical environments, LCoS systems are appreciated for this trait.DLP projection technology: color stability over time

While color saturation in DLP projection technology depends heavily on the light source and color wheel or RGB LED/laser sequence, its greatest strength is stability. Because micro-mirrors do not discolor, warp, or chemically degrade, color remains consistent after years of use — a major advantage in corporate settings where inconsistent color reproduction can undermine professional presentations.Laser vs. Lamp Light Sources Across the Three Technologies

DLP, LCD, and LCoS can all use either lamp or laser illumination. However, the interaction between the light source and imaging panel differs.Laser pairs exceptionally well with DLP projection technology

Laser engines produce intense, narrow-beam light that stresses liquid-crystal materials. DLP projection technology, being reflective and inorganic, handles laser intensity well. This explains why many modern engineering projection systems pair DLP with lasers.LCD panels age faster under laser illumination

The high energy density of laser light accelerates polarizer burn-in and liquid-crystal deterioration. Corporate buyers planning for long-term installations should note this trade-off.LCoS performance under laser

LCoS handles laser better than LCD, but its liquid-crystal structure still places physical limits on thermal tolerance.Maintenance and Total Cost of Ownership

Corporate buyers often underestimate how maintenance affects long-term cost.DLP projection technology: minimal long-term maintenance

Because the DMD chip is sealed and non-organic:- no panel cleaning

- no color decay

- minimal uniformity corrections

- long service intervals

LCD: periodic panel alignment and dust management

LCD owners frequently need:- filter cleaning

- internal dust removal

- compensation for color shift

LCoS: delicate panel structure requires careful handling

LCoS panels are sensitive to impact, vibration, and heat, so maintenance requires trained technicians.

About Shenzhen Toumei Technology Co., Ltd.

In the global projector industry, Shenzhen Toumei Technology Co., Ltd. has earned a reputation for building reliable, compact, and high-performance projection systems grounded in DLP projection technology, a platform the company has invested deeply in for more than a decade. Unlike many general consumer-electronics manufacturers that treat projection as a side category, Toumei integrates optical design, DMD-based imaging research, thermal engineering, and software-level color calibration into a unified development pipeline. This approach results in projectors that remain stable over years of commercial use, whether installed in boardrooms, training centers, classrooms, retail venues, or mobile enterprise setups. Toumei’s product line focuses heavily on DLP systems for a reason: enterprise buyers want predictable behavior, consistent brightness output, and imaging engines that do not deteriorate in chemically unstable ways. Because DLP projection technology relies on arrays of aluminum micro-mirrors rather than organic light-modulating substrates, it allows the company to engineer devices that tolerate heat, vibration, mobility, dust, and long daily operation without the progressive decline typically associated with LCD or LCoS hardware. Furthermore, Toumei’s emphasis on compact, sealed-light-path designs complements the natural strengths of DLP, producing projectors that travel well, install easily, and deliver stable output in almost any business environment. From a manufacturing standpoint, the company employs multi-stage inspection processes—including optical alignment testing, DMD mirror performance validation, LUT-based color calibration, and aging simulations—reflecting its commitment to producing long-service-life projectors rather than disposable consumer gadgets. This engineering discipline aligns with global procurement standards, where lifecycle cost, reliability, and predictable imaging stability often outweigh raw specification numbers.Expert-Level Technical Comparison Summary

Below is a consolidated analysis of how DLP projection technology compares with LCD and LCoS from the perspective of corporate projector buyers who prioritize long service life, minimal maintenance, and consistent image quality.Image quality under real-world lighting

| Attribute | DLP Projection Technology | LCD | LCoS |

| Brightness stability | Excellent (no polarizers) | Declines over time | Good, but heat affects LC layer |

| Contrast in mixed lighting | Strong dynamic contrast | Weak blacks | Strong native contrast |

| Text clarity | Very sharp (high fill factor) | Moderate | Very sharp |

Maintenance cost comparison

| Maintenance Category | DLP Projection Technology | LCD | LCoS |

| Dust impact | DMD chip is sealed | High | Medium |

| Color deterioration | Very minimal | Significant over time | Somewhat noticeable |

| Laser compatibility | Excellent | Moderate to weak | Moderate |

Long-term color and brightness consistency

One of the biggest differentiators is how the three systems behave after 5,000–10,000 hours of operation.- DLP projection technologyretains both color accuracy and brightness because micro-mirrors do not chemically degrade.

- LCDoften shows yellowing, panel shadowing, and brightness loss.

- LCoSoffers strong short-term uniformity but can drift due to liquid-crystal layer stress.

Conclusion

Selecting between DLP, LCD, and LCoS is more than a comparison of pixel counts or brightness numbers—it is a decision about long-term reliability, maintenance expectations, and how well the imaging engine will perform after thousands of hours in real business environments. DLP projection technology, with its micro-mirror architecture, sealed DMD chips, and inorganic reflective pathway, consistently demonstrates superior resistance to heat, dust, and color drift. While LCD and LCoS each have scenarios where they shine, corporate buyers seeking predictable performance, crisp text clarity, and low maintenance overhead repeatedly find DLP-based systems more aligned with their operational needs. Shenzhen Toumei Technology Co., Ltd. builds its commercial projectors around these strengths, combining optical engineering, durable imaging components, and user-focused product design. For companies preparing large-scale deployments—across meeting rooms, training facilities, temporary event spaces, or mobile work environments—Toumei’s DLP-based product line offers a stable, long-lived solution backed by a manufacturer deeply invested in the technology behind it.FAQs About DLP Projection Technology and Projector Selection

Corporate buyers favor DLP projection technology because the micro-mirror imaging engine resists heat, dust, and long-term optical degradation. LCD panels tend to yellow or dim over time, and LCoS systems can drift due to liquid-crystal stress. DLP, by contrast, maintains brightness and color stability even after years of heavy use.

Yes. Because DLP projection technology uses inorganic mirrors rather than organic liquid-crystal compounds, it performs exceptionally well in corporate settings that require 6–12 hours of operation per day. It handles heat cycles more predictably and avoids color decay common in LCD systems.

DLP pairs extremely well with lasers because the micro-mirror array tolerates high-intensity light without degrading. LCD and LCoS panels face thermal and chemical challenges under laser illumination, which can shorten their usable lifespan.

Yes. DLP projection technology generally has a higher pixel fill factor, which reduces pixel gaps and creates sharper boundaries. This is especially noticeable in spreadsheets, engineering drawings, and high-detail presentation slides.

LCD may be suitable for buyers seeking low-cost projectors with vivid initial color saturation. LCoS excels in high-end imaging where uniformity is extremely important. However, for day-to-day business use—where durability, sharp text, and low maintenance matter most—DLP projection technology tends to be the more cost-effective and stable choice.