Have you ever thought about how a small chip can totally change whole factories? Picture this. In a busy car assembly line, spot-on imaging catches flaws before they turn into big headaches. That’s the cool side of DLP technology with Texas Instruments right at the heart. It pushes limits way past basic movie nights. In factory setups, it’s all about being tough and sharp. Let’s jump in.

Understanding DLP Technology Basics

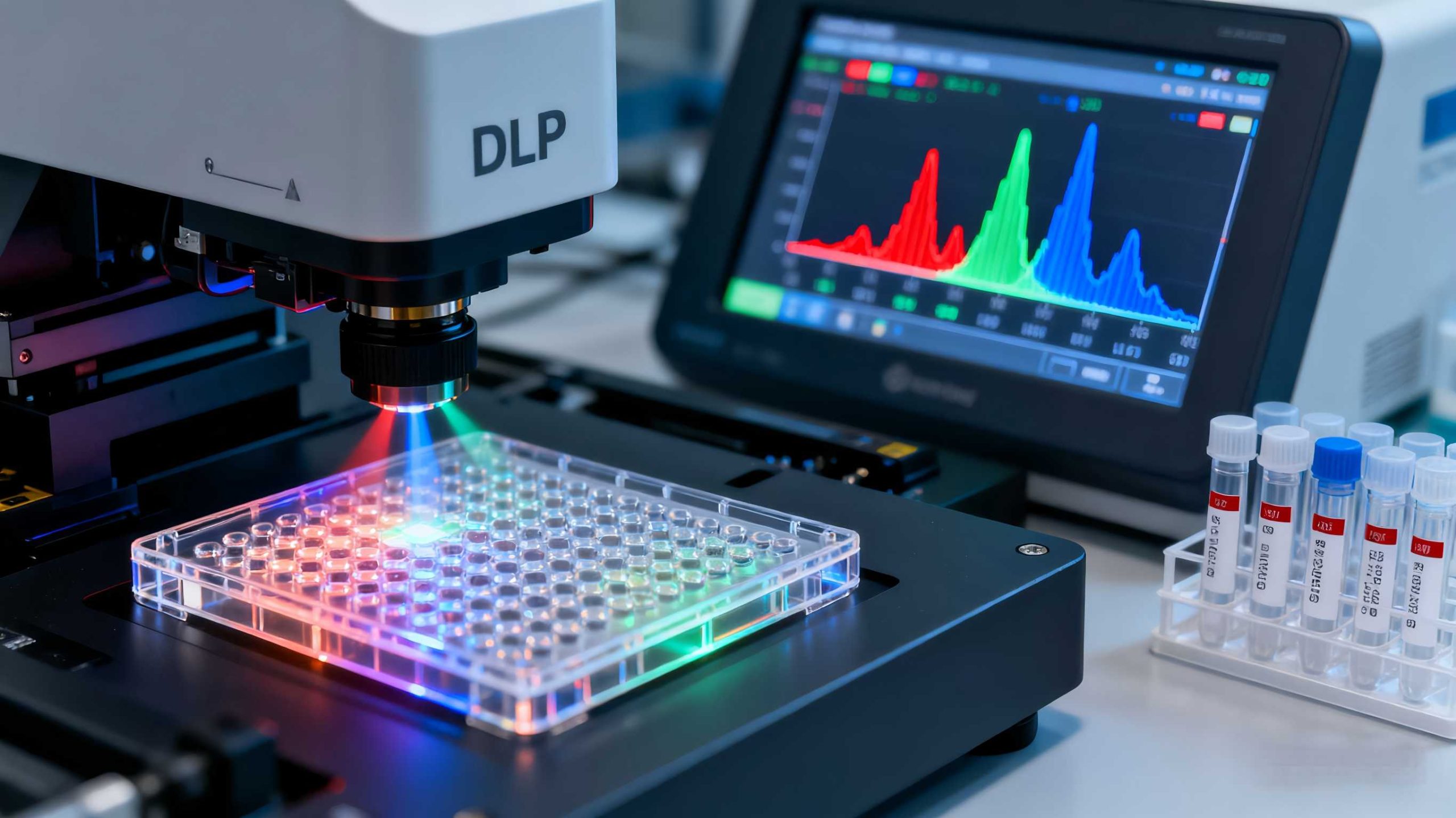

DLP stands for Digital Light Processing. It’s not some fancy term. It works with millions of tiny mirrors on a chip to handle light and make images. Each mirror tips to bounce light through a lens or off it. This builds pictures one pixel at a time. Pretty quick, huh? Texas Instruments started this back in the late ’80s. And now, it’s grown into a real powerhouse for clear, bright displays.

What lets it work well in rough spots? Those mirrors flip states thousands of times each second. They give sharp views even in bad light. Colors don’t fade. DLP chips deal with heat and dirt no problem. I recall talking to an engineer once. He raved about it for checks in metal shops. The clearness slashed inspection times by half.

But it’s not all geek talk. Think of it like a super-fast digital flip book. Light bounces around to form stuff from plans to 3D shapes. In factory solutions, this means easy fit into machines that need exact work without hassle.

The Texas Instruments Edge in DLP

Texas Instruments didn’t just come up with DLP. They honed it for real tough jobs. Their DMD chips are the core. These pack up to 8 million mirrors in one square centimeter. That’s tighter than a rush-hour train in New York.

In factory uses, TI’s stuff stands out because it’s made strong. It uses little power, so less heat builds up. That’s key in tight plant areas. Also, their chips work with waves outside normal light—like UV for setting inks or IR for detecting. Numbers from trade reports show DLP setups with TI parts have failure rates below 0.1% in non-stop runs. That’s much better than old LCD ones.

One odd bit: TI’s first models were bulky. But today? They’re slim and easy to scale. From hand-held gadgets to huge setups, it fits. If you’re in making stuff, this lets you switch parts without ripping everything apart. Good deal.

DLP in Action: Key Industrial Applications

DLP technology with Texas Instruments isn’t stuck in meeting rooms. It’s shaking up trades one light beam at a time.

Manufacturing and Quality Control

On production lines, DLP projectors brighten check stations. Take car welding. Fast cameras teamed with DLP grab issues right away. A report from a Detroit shop showed a 25% drop in fixes after going to TI systems. The projectors cast set light patterns to scan surfaces. They spot bumps or bad fits quicker than you can see.

And it’s not only cars. In gadgets, DLP helps check solder paste. Mirrors switch to make grids that measure small bits—down to microns. I’ve watched systems where workers nab bad lots early. This saves loads in waste.

Medical and Biotech Fields

Hospitals tap DLP for better imaging. Like practice surgeries or finding veins. TI’s chips give bright, true projections even in low-light rooms. One spot in California said outcomes improved in small-cut operations. Thanks to clearer 3D maps.

In labs, DLP runs light etching for chips or growing tissue. UV light shaped by mirrors sets stuff just right. It’s like drawing with light, but for cells. Neat, right?

Automotive and Aerospace

Self-driving cars use LIDAR. And some tie in DLP for steering beams. TI’s tech directs lasers to map streets in a flash. Plane makers use it for wind tests, showing flow on models.

A true story: a jet firm in Europe added DLP to trainers. They cut costs by 30%. Pilots get super-real views without burning gas.

Other Emerging Uses

Don’t skip 3D printing. Printers with DLP set resin layers fast, due to TI’s quick mirrors. Speeds reach 100mm per hour in some. That’s faster than string printers. In energy? Oil platforms use it for far-off checks with drones that have small projectors.

Why DLP Excels in Industrial Environments

Toughness matters most. TI’s DLP chips take shakes up to 10G. Ideal for plant floors. Power wise? They use little—often below 5 watts for main work. This keeps bills low in round-the-clock ops.

Contrast hits over 1000:1. Details stand out in lit storage spots. Colors stay true, covering 90% of Rec.709 norms. Here’s some quick wins in bullets:

- Long Life: Mirrors hold up over 100,000 hours with no drop.

- Easy to Grow: From pocket tools to wall-big screens.

- Simple Hook-Up: Pairs with stuff like Android for clever controls.

- Money Savers: Cuts breaks; one plant got payback in six months.

But honestly—nothing’s perfect. Dirt can mess it up, so closed lenses are needed. Yet in managed places, it’s hard to beat.

Check this fast chart comparing DLP to old tech in factory work:

Aspect | DLP with TI | Traditional LCD |

Lifespan | 100,000+ hours | 20,000-50,000 hours |

Power Use | Low (under 10W) | Higher (20W+) |

Contrast | High (2000:1+) | Medium (500:1) |

Heat Tolerance | Excellent | Moderate |

Cost per Unit | Mid-range | Lower initial |

Spot the win? It’s for the long haul.

Challenges and Future Trends

No gadget lacks snags. Fitting it in can be hard if your gear’s old. Fix? Try small—test one spot first. Looking ahead, count on more AI links. Picture projectors that tweak themselves for room light, boosted by TI’s new chips.

Quantum dots could boost hues more. With Industry 4.0, DLP might connect to smart nets for fix predictions. Thrilling stuff coming.

I stopped by a factory once. They rigged a DLP for AR layers on machines. Staff loved it—upped output by 15%. Small tweaks like that keep it lively.

Toumei Projector Projector: Your Go-To DLP Technology Supplier

Hunting for solid DLP options? Check out Toumei Projector. Started in 2013 in Shenzhen, this tech group focuses on DLP smart projectors and linked gear. They’ve grabbed China’s national high-tech stamp. And they hold more than 50 patents. These cover optics to code changes.

Toumei Projector does more than build boxes. They give full OEM/ODM help. That includes custom boards, cases, and even system tweaks for your factory needs. Their lines make units under ISO 9001 rules. They stress quality from putting together to wear tests. With big bucks in R&D—millions—they’re breaking ground. Like movable projectors with angle shifts or bright models for hard spots.

What makes them different? They put users first. They blend TI’s DLP smooth. This ensures tough, quick products ready for plant grind. Need small ones for field jobs or strong ones for shops? Toumei Projector’s on it. Their crew—young and fresh—manages all, from sketch to ship.

And speaking of their background, Toumei Projector kicked off as one of the early players in DLP smart projectors in China. They mix making, selling, and research. All to hand out smart projection and 3D stuff. Their goal? Bring top tech to everyday life with fresh ideas. Strength-wise, they’ve got national nods and loads of patents. They mainly do full solutions for global folks. Their setup covers design in light, code, hardware, structure, molds, assembly, and tests. They follow ISO standards for quality and green ops. This keeps things improving. Their aim: please customers first, keep innovating. So everyone works with users in mind—team up honest, make precise, and get better always.

From their docs, they’ve poured tens of millions into R&D since 2016. Applied for over 30 IP certs. Registered bunches of patents and inventions. And they plan more cash for development to stay ahead. In 2022, more tech came. Their list shows stuff like appearance designs for projectors, software for UIs, video apps on Android. Even utility models for portable vertical ones or angle-adjust smart projectors.

They talk about dedication, sincerity, trust, accountability. Spot good in partners and help out. Own lines give edges in resources, costs, quality, edge over rivals, bend easy, new ideas on their own, quick answers, and lasting growth. This boosts their spot in the market.

Conclusion

To wrap it up, DLP technology with Texas Instruments is more than just projection. It’s a real shifter for factory solutions. From speeding up plant floors to making medical views exact. Its range really shows. As trades grow, this tech will stay in front. If you’re shopping, checking spots like Toumei Projector might kick off your next step. What do you think—set to brighten your work?