Shenzhen Toumei Technology Co., Ltd., founded in 2013 and based in Shenzhen, China, specializes in Texas Instruments DLP micromirror technology for smart projection applications. The company integrates research, development, production, and sales, with deep capabilities in optical design, software-hardware integration, structural engineering, mold development, assembly, and testing. Holding more than 50 patents, Toumei delivers comprehensive solutions for projection systems, including advancements in ultra short throw configurations and associated sensor technologies. Rigorous quality controls and a focus on precision support dependable performance in diverse deployment scenarios.

Shenzhen Toumei Technology Co., Ltd., founded in 2013 and based in Shenzhen, China, specializes in Texas Instruments DLP micromirror technology for smart projection applications. The company integrates research, development, production, and sales, with deep capabilities in optical design, software-hardware integration, structural engineering, mold development, assembly, and testing. Holding more than 50 patents, Toumei delivers comprehensive solutions for projection systems, including advancements in ultra short throw configurations and associated sensor technologies. Rigorous quality controls and a focus on precision support dependable performance in diverse deployment scenarios.

Fundamentals of ToF Autofocus in Projectors

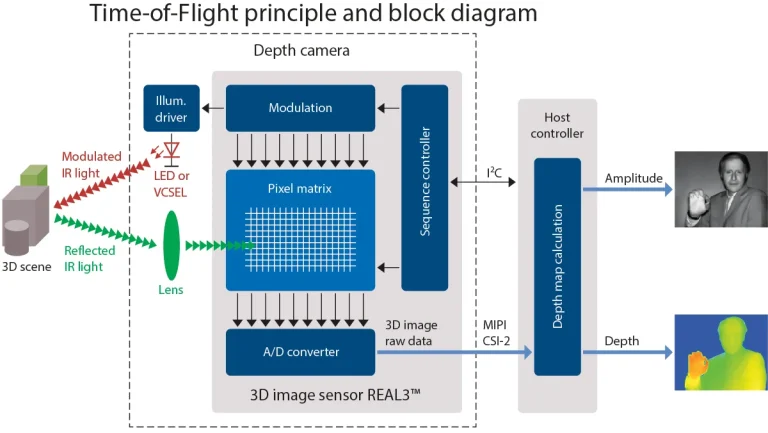

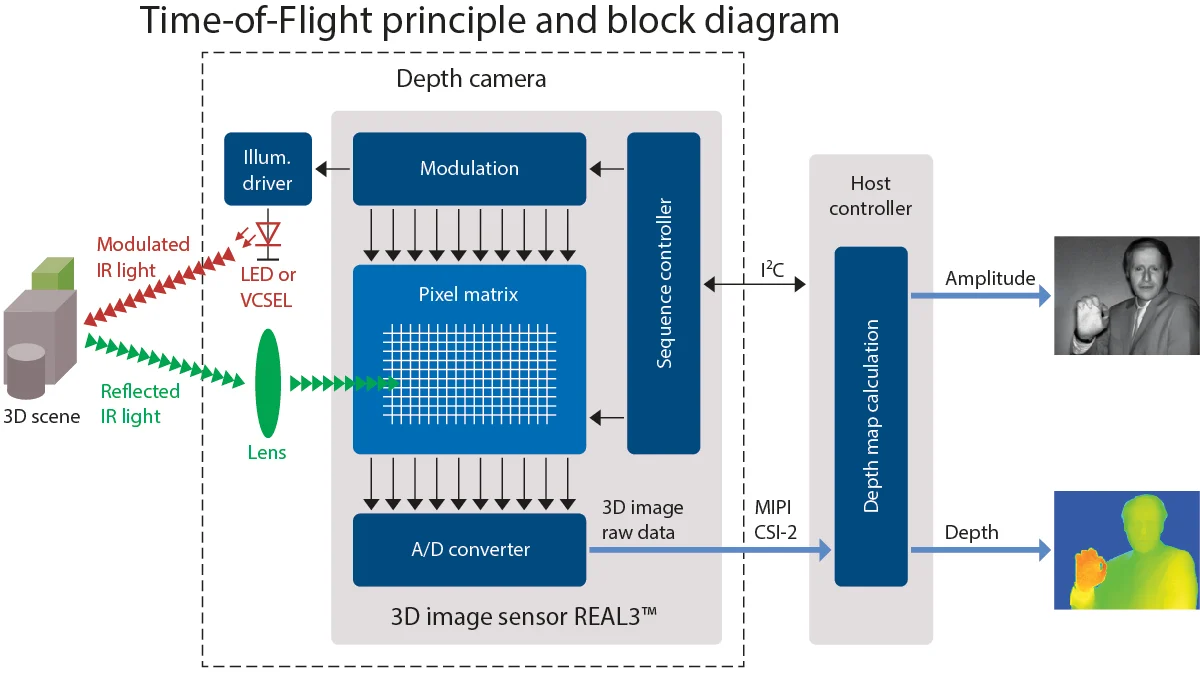

ToF autofocus operates on a straightforward principle: a laser pulse travels to the target surface and returns, with the round-trip time determining distance since light speed remains constant. In projectors, an infrared laser emitter sends out short pulses, typically in the nanosecond range. Photons reflect back to a sensitive receiver array, where precise timing circuitry calculates the delay. Distance equals half the time multiplied by the speed of light. This method differs markedly from contrast-detection autofocus, which analyzes image sharpness through captured frames, or phase-detection systems that compare light paths. ToF requires no image content analysis. It functions equally well on plain walls, textured surfaces, or even dark fabrics, as long as sufficient photons return. In ultra short throw projectors, where throw ratios drop to 0.22:1 and projection angles grow steep, small distance variations across the field cause noticeable focus falloff. A single-point sensor might suffice for longer-throw models, but multi-point arrays like the 8×8 laser ToF in the Toumei S1 scan multiple zones simultaneously, averaging or weighting readings to map the projection plane more accurately. Real deployments highlight the advantage. Consider a bedroom setup where the projector sits on a nightstand one evening and moves to a shelf the next. Manual focus adjustments disrupt viewing flow. ToF enables the system to trigger on power-up or movement detection, recalculating distance in milliseconds and driving the lens motor accordingly. The result stays consistent sharpness edge-to-edge, even when the surface tilts slightly or includes minor irregularities.Hardware Signal Chain: From Emitter to Lens Motor

The signal chain begins with the laser emitter, usually an invisible infrared diode operating at wavelengths around 850–940 nm for eye safety and minimal interference with visible projection. Pulses emit in bursts—often 10–100 ns wide—at repetition rates sufficient for real-time updates, sometimes 30 times per second in advanced implementations. Reflected photons reach the receiver, typically a single-photon avalanche diode (SPAD) array or similar high-sensitivity detector. SPADs register individual photon arrivals with picosecond timing resolution. Time-to-digital converters (TDCs) measure the exact interval between emission and detection, converting nanoseconds into distance data with sub-centimeter accuracy over typical projector ranges (0.5–3 meters). A microcontroller or dedicated SoC processes this raw timing information. Algorithms filter noise—rejecting outliers from stray reflections or ambient light—and compute a representative distance per zone in the multi-point array. In the Toumei S1, the 8×8 grid divides the field into 64 measurement points, allowing the system to detect tilt, curvature, or unevenness across the projected area. Weighted averaging prioritizes central zones for primary focus while using peripherals to inform keystone adjustments. Processed distance maps translate directly to lens motor commands. Stepper motors or voice-coil actuators shift the projection lens along its optical axis, adjusting focal length to match the measured plane. Closed-loop feedback sometimes verifies the adjustment by triggering a secondary ToF scan, though most implementations rely on calibrated motor steps per distance unit. Thermal effects appear here as well. Emitter wavelength drifts slightly with temperature, and receiver timing circuits exhibit minor variations. The chain includes temperature sensors near key components, feeding data to compensation routines that adjust timing offsets or gain. In practice, the entire chain—from pulse emission to motor halt—completes in under a second for the Toumei S1. Low-latency processing keeps the system responsive during dynamic use, such as ceiling-mounted units in conference rooms where table height changes slightly between meetings.Calibration Workflow: Factory and Field Precision

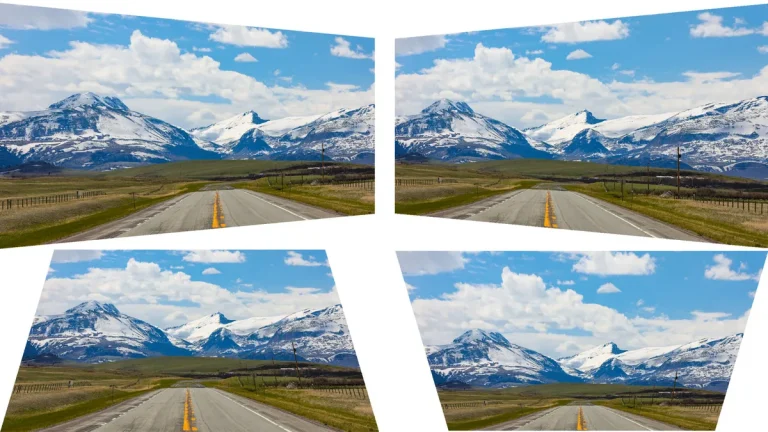

Factory calibration establishes the baseline relationship between ToF readings and actual focus motor positions. Multiple test stations measure distances at standardized points—0.5 m, 1 m, 2 m, 3 m—across flat, matte targets under controlled lighting and temperature. Each zone in the array receives individual characterization, building lookup tables that map raw time-of-flight values to precise distance estimates. Surface variations enter the equation next. Glossy test panels simulate high-reflectivity curtains, while low-reflectivity fabrics mimic dark walls. Calibration software records return signal strength and adjusts thresholds or gain to minimize bias. Temperature sweeps—from 0°C to 40°C—expose drift characteristics, generating polynomial corrections or piecewise linear approximations stored in firmware. Field calibration activates on initial setup or detected change. The Toumei S1 powers the 8×8 laser ToF array, scans the projection surface, and computes a composite distance map. Central points dominate focus decisions, while edge readings feed into real-time keystone correction algorithms. The system applies factory-derived offsets automatically, ensuring the lens moves to the correct position without user input. Periodic recalibration occurs during extended sessions if internal sensors detect temperature shifts beyond a threshold. Firmware updates occasionally refine these tables based on field data aggregated anonymously from deployed units. Challenges arise from assembly tolerances. Slight variations in emitter-receiver alignment or lens mount position require per-unit trimming during production. The workflow includes post-assembly verification scans against known distances, rejecting outliers to maintain batch uniformity.Temperature Drift Compensation

Temperature changes introduce measurable errors in ToF systems. The laser diode wavelength shifts approximately 0.3 nm per °C, altering pulse timing interpretation. Receiver electronics exhibit propagation delay variations, and mechanical components expand differentially—lens barrels, mounts, or sensor housings. Compensation begins with onboard thermistors placed near the emitter, receiver, and DMD. Readings feed into algorithms that apply pre-characterized corrections. Simple implementations use lookup tables indexed by temperature; more advanced ones fit quadratic or cubic polynomials to observed drift curves during factory sweeps. In the Toumei S1, RGB-LED illumination generates lower peak heat than single-laser sources, reducing overall thermal gradients. Multiple 6 mm copper heat pipes and finned stacks distribute heat evenly, keeping the optical train stable. The ToF array benefits from this design—drift stays minimal even after hours of operation, avoiding the gradual defocus seen in higher-heat systems. Field experience shows effectiveness. During a continuous 4-hour session projecting HDR content, internal temperatures rise 15–20°C. Without compensation, focus might shift by several millimeters at the lens. Calibrated routines hold deviation below 1 cm, preserving edge sharpness on a 120-inch image.Reflectivity Errors and Surface Compensation

Return signal strength varies dramatically with surface properties. Matte white walls reflect strongly, yielding clean, high-amplitude pulses. Glossy curtains or dark fabrics return fewer photons, increasing noise or introducing bias toward closer estimates due to multipath reflections. The 8×8 array mitigates single-point failures. If one zone detects weak returns, neighboring points contribute more to the average. Adaptive gain adjusts emitter power or receiver sensitivity dynamically, boosting faint signals without saturating bright ones. Threshold filters discard invalid readings—too short (internal reflections) or too noisy. In challenging scenarios, such as silk curtains with low diffuse reflection, the system may extend measurement time or use fallback strategies like prioritizing central zones. Pairing with dedicated UST ALR screens minimizes issues, as these surfaces provide consistent, high-gain reflection optimized for oblique incidence. Deployments confirm robustness. On a slightly glossy bedroom wall, focus locks accurately in one second. Switching to a dark fabric curtain triggers a brief secondary scan, yet the final image remains sharp without visible hunting.Mass-Production Consistency: Achieving Uniform Performance

Consistency across thousands of units demands tight control at every stage. Sensor tolerances—emitter wavelength spread, receiver timing jitter—introduce unit-to-unit variability. Assembly alignment of the ToF array relative to the lens axis must stay within microns to avoid systematic offsets. Production testing includes automated stations that verify distance accuracy at multiple points and temperatures. Units failing predefined limits undergo recalibration or component replacement. Firmware stores per-unit correction coefficients, loaded during final programming. Yield optimization focuses on supply chain stability. Matched batches of laser diodes and SPAD arrays reduce variance. In-house optical and structural expertise at Toumei supports precise integration, minimizing drift from mechanical play. The outcome appears in field reliability. Batches maintain focus performance within tight margins, supporting OEM integrations where predictable behavior matters for custom enclosures or software ecosystems.Toumei S1 in Practice: ToF Autofocus Performance

The Toumei S1 combines its 0.22:1 throw ratio and 135% offset with the 8×8 laser ToF array for seamless operation. Projecting 100 inches from 25 cm, the system adapts instantly to repositioning—low console to high shelf—delivering sharp Full HD imagery enhanced by XPR technology.

In a typical office setup, ceiling mounting introduces tilt. Multi-point scanning detects the angle, applying focus and keystone corrections simultaneously. 700 ANSI lumens cut through ambient light, while 95% uniformity and 85% BT.2020 gamut preserve detail across the frame. Quiet 27 dB operation keeps adjustments unobtrusive.

Connectivity—HDMI 2.1 with eARC, WiFi 6, Bluetooth—integrates without compromising the optical chain. HDR10+ support stresses focus accuracy on high-contrast scenes; the ToF system holds steady.

The Toumei S1 combines its 0.22:1 throw ratio and 135% offset with the 8×8 laser ToF array for seamless operation. Projecting 100 inches from 25 cm, the system adapts instantly to repositioning—low console to high shelf—delivering sharp Full HD imagery enhanced by XPR technology.

In a typical office setup, ceiling mounting introduces tilt. Multi-point scanning detects the angle, applying focus and keystone corrections simultaneously. 700 ANSI lumens cut through ambient light, while 95% uniformity and 85% BT.2020 gamut preserve detail across the frame. Quiet 27 dB operation keeps adjustments unobtrusive.

Connectivity—HDMI 2.1 with eARC, WiFi 6, Bluetooth—integrates without compromising the optical chain. HDR10+ support stresses focus accuracy on high-contrast scenes; the ToF system holds steady.

Future Directions in ToF Autofocus for Ultra Short Throw Projectors

Advancements target finer resolution arrays, AI-enhanced averaging for noisy environments, and tighter thermal integration. Hybrid approaches may combine ToF with secondary sensors for edge cases. Compact designs like the Toumei S1 set the foundation for broader adoption in space-limited applications.About Shenzhen Toumei Technology Co., Ltd.

Shenzhen Toumei Technology Co., Ltd. has developed specialized expertise in DLP projection since 2013. Headquartered in Shenzhen, the company merges optical innovation with full manufacturing oversight. A dedicated R&D team advances projection systems, securing numerous patents and providing solutions that align performance with practical deployment. Strict quality protocols and specialized production lines deliver consistent results, establishing Toumei as a reliable partner for projection requirements across various contexts.Conclusion

ToF autofocus transforms ultra short throw projector usability by delivering rapid, accurate focus through direct distance measurement, sophisticated hardware chains, rigorous calibration, and thoughtful compensation for temperature and reflectivity effects. Mass-production consistency ensures these benefits scale reliably. The Toumei S1 demonstrates effective implementation, supporting stable performance in demanding setups. Continued engineering progress will further refine reliability and adaptability.FAQs

ToF autofocus emits laser pulses, measures return time from the surface, and calculates distance to drive the lens motor precisely, enabling one-second focus even on varied surfaces.

Temperature shifts cause wavelength changes in the laser and timing variations in receivers, leading to distance measurement errors unless compensated with onboard sensors and correction algorithms.

High or low surface reflectivity alters return signal strength, introducing noise or bias; multi-point arrays and adaptive gain help average readings and maintain accuracy.

Factory calibration with multi-distance and temperature testing, per-unit correction tables, and tight component tolerances during assembly maintain uniform performance across batches.

Multi-point arrays like 8×8 scan multiple zones, reducing errors from single-point noise or tilt, and provide better mapping for focus and keystone in uneven setups.