Shenzhen Toumei Technology Co., Ltd., established in 2013 and headquartered in Shenzhen, China, concentrates solely on DLP smart projection technology. The organization manages comprehensive operations encompassing research, development, production, and sales, with a core focus on Texas Instruments DLP micromirror devices. Proficiency includes optical engineering, integrated software-hardware development, structural mechanics, mold creation, assembly processes, and stringent validation. Holding more than 50 patents and maintaining regular product iterations, Toumei provides full-spectrum projection solutions, encompassing progress in ultra short throw implementations. Commitment to quality oversight and engineering accuracy delivers consistent outcomes across diverse operational scenarios.

Shenzhen Toumei Technology Co., Ltd., established in 2013 and headquartered in Shenzhen, China, concentrates solely on DLP smart projection technology. The organization manages comprehensive operations encompassing research, development, production, and sales, with a core focus on Texas Instruments DLP micromirror devices. Proficiency includes optical engineering, integrated software-hardware development, structural mechanics, mold creation, assembly processes, and stringent validation. Holding more than 50 patents and maintaining regular product iterations, Toumei provides full-spectrum projection solutions, encompassing progress in ultra short throw implementations. Commitment to quality oversight and engineering accuracy delivers consistent outcomes across diverse operational scenarios.

Why Ultra Short Throw Projectors Face Unique Optical Challenges

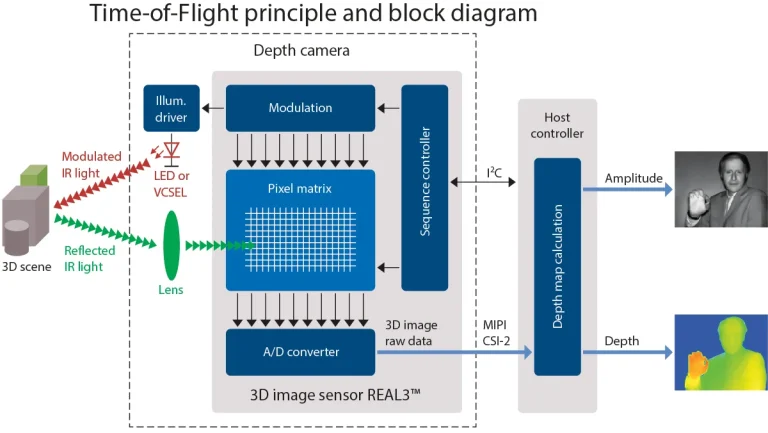

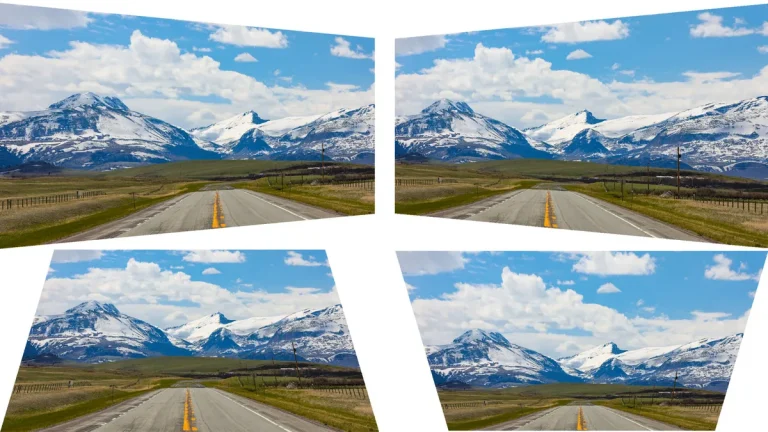

The fundamental issue originates from basic geometry. Traditional projectors transmit light over extended, linear paths, permitting relatively simple lens groupings and broadly tolerant focus planes. Ultra short throw configurations compress the optical path through abrupt folding—several mirrors combined with aspherical elements redirect rays at pronounced angles to span broad fields from close proximity. This condensed, reflective arrangement exaggerates minuscule misalignments, material expansions, or thermal gradients. Light scattering escalates within these paths. Rays impact the screen at highly oblique incidences, converting subtle surface irregularities—gentle undulations on a wall, minor textural variations, or slight curvatures—into pronounced shadows, hotspots, or interference patterns. Uniformity deteriorates because the optical distance to the screen center diverges considerably from peripheral zones; central regions remain proximal while edges and corners extend farther, resulting in progressive focus degradation absent exact countermeasures. Distortion patterns develop intrinsically from the expansive angular field. Barrel distortion bows lines outward, pincushion pulls them inward, most evident in grid test patterns, architectural lines, or geometric content. Pixel drift manifests as thermal effects cause incremental component expansion—mirrors displace by fractions of a micron, color channels separate at boundaries, or individual pixels migrate over operational duration. These phenomena scale aggressively with image size, where allowable tolerances contract to sub-micron levels. Field experience underscores the pattern repeatedly. Acute angles mandate exceptional registration precision; minor mechanical vibrations, floor settling, or cabinet flex introduce edge degradation. Digital keystone or warp corrections provide partial relief but incur resampling penalties—overall sharpness diminishes, artifacts emerge, or processing latency increases. The persistent engineering objective centers on safeguarding native optical quality while enabling feasible real-world placement. Aspherical lenses represent a cornerstone in addressing spherical aberration and field curvature in ultra short throw systems. Unlike spherical surfaces, aspheres vary curvature progressively from center to edge, correcting coma, astigmatism, and distortion more efficiently across wide fields. In UST designs, large-diameter aspherical elements often form the final refractive stage, minimizing off-axis aberrations that conventional lenses struggle to contain. Manufacturing these surfaces, however, poses substantial hurdles. Precision diamond-turning or multi-axis polishing achieves the required sub-micron form accuracy, yet metrology remains demanding—interferometric testing or computer-generated holograms verify deviations that even slight errors in the nanometer range shift ray paths noticeably. Freeform mirrors add another layer of sophistication. These non-rotationally symmetric reflective surfaces permit customized wavefront control in compact footprints, enabling extreme throw reduction without proportional increases in element count or path length. Freeform optics correct higher-order aberrations that standard conic sections cannot, distributing light more evenly and reducing field-dependent distortion. Fabrication challenges intensify here: multi-axis CNC machining followed by ion-beam figuring or magnetorheological finishing achieves the necessary surface roughness below 1 nm RMS, while alignment tolerances tighten to arc-second levels. Misalignment by even 0.1 degrees can introduce astigmatic blur or coma at corners. Thermal drift compounds these sensitivities. Coefficient of thermal expansion mismatches between lens glass, mirror substrates, and mounting structures cause differential growth during warm-up or sustained operation. In folded paths, a 1-2°C rise might displace a mirror by microns, shifting pixel registration and inducing color fringing or focus migration. RGB-LED sources mitigate some risk through distributed, lower-peak heating compared to concentrated laser diodes, yet active cooling—copper heat pipes, synchronized fans—remains essential to stabilize the optical train. Stray light control emerges as another persistent concern. In complex folded paths, off-axis rays reflect internally, generating veiling glare or contrast loss. Multi-layer anti-reflective coatings on refractive elements and absorptive baffles around mirrors suppress these unwanted paths, preserving black levels in HDR material where subtle gradients matter most.Real-World Optical Challenges in Action (Toumei S1 Case Study)

Envision a commonplace installation: the projector occupies a low console, projecting upward onto a wall-mounted surface or dedicated screen. The Toumei S1’s 0.22:1 ratio yields a 100-inch frame from roughly 25 cm separation. The 135% offset positions the lens low, channeling light upward to bypass obstructions. Edge softness frequently surfaces initially. Peripheral zones demand extended focal travel relative to the center; without tailored compensation, resolution falls off perceptibly. The S1 counters via its 0.23-inch DMD with XPR pixel-shifting and meticulously calibrated optics, securing uniformity exceeding 95% across the full field. RGB-LED illumination aids decisively—triple-source distribution avoids hotspot-induced drift common in single-laser alternatives, delivering stable thermal profiles over hours. Color fringing or channel separation appears on sharp transitions, amplified by ambient illumination. The S1’s coverage of 85% BT.2020 gamut alongside 500:1 FOFO contrast upholds fidelity, though deployments emphasize wall flatness as decisive. Subtle convexity produces ripple-like distortions; integration with a UST Fresnel ALR screen restores even response and elevates effective uniformity. Pixel alignment endures through inherent low-heat behavior—27 dB acoustic output from copper-pipe cooling maintains equilibrium. During 120-inch bedroom projection, minor positional shifts occur, yet the 8×8 multi-point laser TOF sensor cluster executes autofocus in one second and applies dynamic keystone, curtailing manual interventions that erode native optics. These observations demonstrate engineered mitigation of intrinsic constraints. The A4-class chassis limits placement variability, while 700 ANSI lumens accommodates typical room light without aggressive digital enhancement. Thermal equilibrium extends further. Copper conduits spread heat uniformly from LEDs and DMD, averting localized warping that displaces reflective elements. This consistency supports prolonged sessions where cumulative effects otherwise erode focus or introduce skew.How to Overcome Ultra Short Throw Optical Challenges

Resolution prioritizes mechanical precision above algorithmic compensation. Level the projector rigorously across axes with a precision bubble instrument. Register it centrally to the intended field; lateral offsets measured in millimeters compound peripheral distortion exponentially. Surface conditioning holds comparable importance. Sustain flatness deviations below 2-3 mm throughout the projection zone; oblique rays magnify variances dramatically. Textured coatings disperse light irregularly—uniform or purpose-built finishes produce markedly cleaner outcomes. Uniform focus gains from restrained keystone application. Digital resampling interpolates, diminishing detail. The S1’s automated sensors accommodate slight deviations natively, preserving integrity. Manual corrections confine to localized warp rather than global shifts. Ambient variables shape final results. Direct illumination erodes contrast—strategic placement or shading preserves performance. ALR surfaces augment blacks and uniformity without inflating source demand. Structured deployment proceeds methodically: Confirm surface planarity across the full span with a rigid straightedge. Establish height alignment so image lower edge coincides with console top. Horizontally center employing overlaid grids. Initiate autofocus and evaluate peripheral definition. Utilize diagnostic patterns—grids disclose curvature, resolution charts expose falloff gradients. Refine pitch and roll adjustments on mounting hardware. Perform calibration matching actual viewing scenarios—HDR content reveals uniformity limitations most acutely. Track stability across repeated cycles; LED characteristics restrain drift. Document positional data for reproducible setups. Revalidate following environmental alterations such as thermal cycling or structural settling. These protocols render inherent complexities into controlled, repeatable execution. Further refinement addresses stray light rigorously. Internal baffling combined with broadband anti-reflective treatments on refractive and reflective surfaces curtails flare from rogue rays, safeguarding shadow detail in cinematic sequences. In brighter environments, this distinction maintains separation where diffuse scatter otherwise compresses dynamic range.Toumei S1 Optical Performance in Context

The S1 differentiates through calculated selections. Its 0.22:1 ratio and substantial offset constrain spatial demands while rendering enhanced Full HD detail. 700 ANSI lumens facilitate practical viewing in illuminated spaces, complemented by MEMC for fluid motion handling without exacerbating optical artifacts.

Uniformity beyond 95% derives from optimized distribution across the DMD plane. Low acoustic signature and thermal management sustain equilibrium during extended runtime—essential where session consistency defines utility.

Interface provisions—HDMI 2.1 eARC, WiFi 6, Bluetooth—facilitate integration while upholding signal purity. Rapid autofocus alongside adaptive correction accommodates fixed or variable deployments, centering on optical excellence.

The S1 differentiates through calculated selections. Its 0.22:1 ratio and substantial offset constrain spatial demands while rendering enhanced Full HD detail. 700 ANSI lumens facilitate practical viewing in illuminated spaces, complemented by MEMC for fluid motion handling without exacerbating optical artifacts.

Uniformity beyond 95% derives from optimized distribution across the DMD plane. Low acoustic signature and thermal management sustain equilibrium during extended runtime—essential where session consistency defines utility.

Interface provisions—HDMI 2.1 eARC, WiFi 6, Bluetooth—facilitate integration while upholding signal purity. Rapid autofocus alongside adaptive correction accommodates fixed or variable deployments, centering on optical excellence.

Future Directions in Ultra Short Throw Optical Design

Development targets enduring limitations. Refined aspherical profiles and precision alignment mechanisms diminish drift exposure. Evolving sensor suites enhance adaptive response. LED-dominant and hybrid illumination ensure thermal consistency with minimal perturbation. Indications suggest accelerated penetration into constrained environments. Reliable, compact architectures like the S1 facilitate dependable expansive visuals absent elaborate preparation.About Shenzhen Toumei Technology Co., Ltd.

Shenzhen Toumei Technology Co., Ltd. maintains specialized proficiency in DLP projection since 2013. Located in Shenzhen, the entity integrates optical progression with end-to-end manufacturing oversight. A focused R&D contingent propels system advancements, accumulating patents and furnishing solutions that harmonize capability with operational simplicity. Stringent quality frameworks and dedicated production infrastructure assure uniform delivery, establishing Toumei as a credible authority for projection demands in varied domains.Conclusion

Ultra short throw projection realizes expansive scale within confined footprints, although optical challenges—light path elaborations, distortion characteristics, and uniformity prerequisites—necessitate deliberate resolution. Precise registration, surface refinement, and intentional engineering transform limitations into assets. The Toumei S1 exemplifies targeted resolution of these demands, yielding stable, defined imagery from abbreviated distances. Achievement rests on mechanical exactitude and contextual alignment. Sustained refinement positions ultra short throw systems to extend immersive presentation possibilities further.FAQs

Edge softness originates from disparate focal lengths across the field—corners position farther from the projection origin than central areas in acute-angle geometries. Ultra short throw architectures intensify this disparity, necessitating exact optical compensation to uphold definition uniformly.

Focus on physical registration preceding digital keystone engagement. Align the unit centrally with precision, level thoroughly, and verify surface integrity. Minimize algorithmic corrections, which resample and soften detail; native positioning delivers maximal sharpness.

Pixel drift commonly stems from thermal expansion relocating optical components throughout runtime. RGB-LED configurations generate reduced heat concentrations than alternatives, attenuating the phenomenon. Robust thermal dissipation and controlled surroundings further constrain drift during prolonged activity.

Screen composition influences uniformity profoundly—irregular surfaces produce localized hotspots or undulations from grazing incidence. Purpose-designed UST ALR materials improve planarity response and diffusion control, elevating uniformity and contrast relative to conventional walls.

Autofocus contributes meaningfully to sustained focus integrity on diverse substrates. Multi-point laser sensing facilitates swift, accurate compensation for positional deviations, bolstering edge-to-edge resolution with limited operator involvement.