In large-scale commercial deployments, how laser projectors work matters for a simple reason: “the picture looks fine” is not the same as “the projector performs the same way after six months of daily runtime, across multiple sites, under real ambient light, with real operators and real maintenance habits.” For buyers managing multi-location lines—corporate rollouts, education programs, hospitality groups, retail chains, and exhibition installers—laser projection isn’t just a feature. It’s a total cost, uptime, and risk decision.

Laser projectors are best understood as a system: the laser light source, the optical engine, the imaging device, thermal design, control firmware, and calibration strategy all stack together. When procurement teams validate only one or two variables—say, brightness and resolution—scale-up issues show up later as inconsistent focus, color drift, thermal throttling, nuisance returns, or “random” complaints that are rarely random.

This one-stop guide is written for B2B buyers and product teams who want a repeatable decision path: something you can use in RFQs, sample approvals, pre-production checks, and multi-site rollouts—without turning the process into a science project.

The 60-Second Overview: What “Laser” Means in a Projector

A laser projector replaces the traditional lamp with a solid-state laser-based illumination system. That shift changes how the projector starts, how it holds brightness over time, and how maintenance looks across the product life.

In practical terms, a laser light source is valued because it typically supports longer operational life, faster on/off behavior, and reduced dependence on consumable lamp changes. Many mainstream explanations cite laser light sources in the range of roughly 20,000–30,000 hours (often quoted until a meaningful brightness reduction threshold), which is why laser is commonly used in high-use spaces where access and downtime are expensive.

What laser does not do by itself is guarantee a “better image.” The image quality you see is the combined result of the light engine architecture, the imaging path (for example, DLP-based micromirror imaging), the optics, and the signal processing. In large-scale commercial projects, the buyer’s job is to confirm that the system is stable, repeatable, and serviceable—not just impressive on day one.

Two Laser Light Engine Architectures You’ll See on Spec Sheets

If you only remember one thing from this section, remember this: “laser” is not a single technology. There are multiple illumination architectures, and they come with different tradeoffs in color performance, optical complexity, cost structure, and scale reliability.

Laser Phosphor: Why It’s Common in Commercial Runs

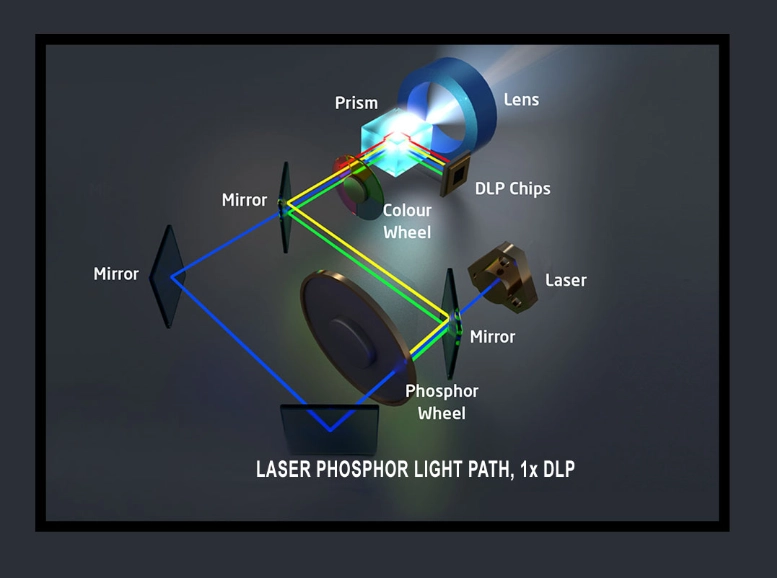

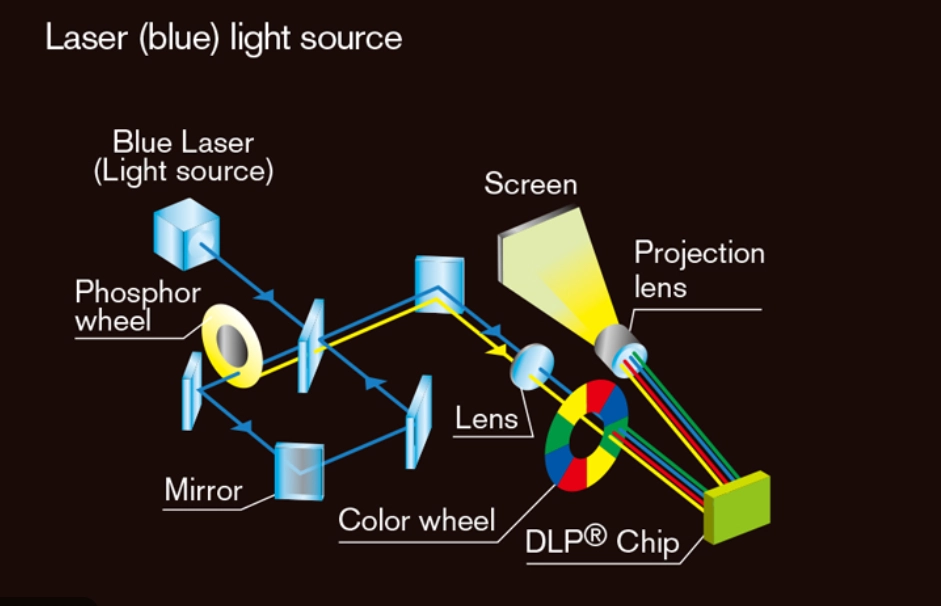

The most common architecture in the broader market is laser phosphor. The basic idea is that a blue laser excites a phosphor material to generate a broader spectrum of light, which is then processed to form the colors needed for the projected image.

For buyers managing multi-location spaces, laser phosphor tends to be attractive because it’s widely deployed, cost-efficient relative to more complex laser architectures, and can be engineered into compact designs. In procurement terms, it’s often the “workhorse” option when you need predictable performance at scale with fewer variables in the optical chain.

That said, laser phosphor systems still demand good engineering discipline. Phosphor components and their operating temperatures influence long-term performance, and any high-throughput deployment will surface variation if thermal management and QC aren’t tight.

RGB Laser: Why It Can Look Great—and Why It’s Tricky to Execute

RGB laser (sometimes described as direct laser) uses separate red, green, and blue lasers to generate the image colors without relying on phosphor conversion. It can deliver strong color performance and a wide color gamut in the right implementation, which is why it’s often discussed for premium experiences and controlled environments.

For B2B procurement, RGB laser introduces a different set of considerations. The optical path can be more demanding. The bill of materials can be higher. There can be additional work needed around speckle management, calibration stability, and thermal behavior.

None of that makes RGB laser “better” or “worse.” It simply makes it different. In large-scale commercial projects, the best architecture is the one that can be validated, produced consistently, and supported after deployment.

From Light to Image: The Optical Path Buyers Should Understand

Most buyers don’t need to become optical engineers, but procurement teams do need a working mental model of what parts of the projector can drive risk. When an issue appears—focus instability, inconsistent color, dust artifacts, brightness non-uniformity—knowing where in the optical path the problem likely lives can save weeks.

A practical model breaks the projector into four functional blocks.

The Light Source and Light Conditioning

Laser illumination starts at the laser module and is conditioned before it reaches the imaging element. Conditioning can include conversion (in laser phosphor designs), wavelength management, and optical shaping. The purpose is to deliver a stable, controlled light field to the imaging system.

In large-scale bottling-style rollouts—high throughput, repeated builds, multiple production batches—light source consistency becomes a manufacturing question. The same nominal light source class can behave differently if heat dissipation, drive current control, and component tolerances vary.

The Imaging Element: DLP Micromirror Imaging in Plain Language

In DLP-based systems, the image is formed by an array of microscopic mirrors that rapidly modulate light. Think of it as high-speed light switching: the mirrors reflect light in a controlled way to create pixel-level brightness values that form the image on screen.

For buyers managing multi-site deployments, the reason this matters is not the theory; it’s what it implies operationally. The imaging element is typically stable and repeatable when paired with a disciplined optical engine and thermal design. If you’re seeing inconsistent images across units, the root cause is often less about “the chip” and more about how the optical engine and calibration are executed.

The Lens and Focus Mechanism: Where Real-World Variability Shows Up

Once the image is formed, the lens projects it onto the surface. This is where mechanical tolerance, alignment, and focus control become visible to end users. In a high-throughput rollout, two patterns show up repeatedly.

First, the “looks sharp in one corner” problem: often a sign of alignment, lens variance, or mechanical assembly tolerance interacting with projection geometry. Second, focus drift over time: typically tied to temperature changes, mechanical movement, or inconsistent calibration.

If your program relies on automatic focus and auto-keystone correction, confirm that the system behaves consistently across your intended installation conditions—not just in a showroom demo. In large-scale commercial projects, the difference between a smooth rollout and an escalation-heavy rollout is often whether the focus and keystone behavior was validated as a system requirement.

Thermal Design: The Quiet Driver of Reliability

Thermals are not glamorous. They are also one of the most common hidden failure modes. Laser illumination can be efficient, but it still generates heat. The optical engine, mainboard, and power components also generate heat, and heat influences both performance and long-term stability.

From our experience in commercial electronics manufacturing, a thermally marginal design can pass short functional tests yet fail later through throttling, brightness decay, fan noise complaints, or component stress. When you’re sourcing at scale, thermal management is not a “nice to have.” It is part of the performance spec.

Why “Looks Fine in the Sample” Can Fail at Scale

This is the section buyers tend to recognize immediately, because it describes what happens in real procurement: the pilot run looks good, then production volume starts, then field feedback gets messy.

In large-scale commercial projects, scale failures usually come from one of four causes: incomplete requirements, uncontrolled variation, misaligned validation, or missing feedback loops between factory testing and real deployment.

Speckle, Perception, and Environment

Laser speckle is a known phenomenon in laser-based imaging. Whether it becomes a real problem depends on the illumination architecture, screen characteristics, viewing distance, and ambient conditions.

In controlled demo environments, speckle may be barely noticeable. In real deployments—bright rooms, textured walls, different screen materials—it can suddenly become a complaint. The procurement takeaway is to validate in a representative environment. If your application is a conference space with bright lighting, validate there. If your application is a museum installation with controlled lighting and a specialty surface, validate there.

High Torque” Doesn’t Mean “Stable Performance” in Projector Terms

Projector programs have their own version of “false torque.” You can have a unit that passes functional testing and still behaves inconsistently in the field because the performance margin is thin.

A common example is focus and keystone: the feature works, but the reliability varies by unit or by thermal state. Another is Wi-Fi stability and streaming performance: it passes in a lab, but the user environment reveals different interference patterns. A third is brightness and fan behavior: the unit meets initial measurements but runs louder or dimmer under sustained high load.

When you treat projector qualification as engineering verification—not a catalog selection—your failure rate typically drops fast.

Tolerance Stack-Up and the “Multi-Site Reality”

For buyers managing multi-location deployments, the same product can behave differently across sites because installation conditions change: throw distance, mounting geometry, ambient light, wall reflectance, and operator setup habits.

That is why a procurement spec should include environment assumptions, not only hardware specs. A unit that is perfect for a dim room may disappoint in a bright room, and that is not a quality issue—it’s a requirement mismatch.

What Specs Matter Most for Commercial Deployment

If your goal is fewer returns and fewer escalations, you need to anchor spec decisions to the actual use case.

Brightness and Ambient Light: Why ANSI Lumens Are Only Step One

Brightness is often presented as a single number, but in commercial use it is experienced as “can the content be read clearly under actual lighting.” ANSI lumens are useful for comparison, but they do not replace scenario testing.

For example, Toumei’s DLP projector lineup includes models listed with brightness points such as 600 ANSI lumens for certain 1080p-class devices and higher output options like 1600 ANSI for other configurations in its catalog. Those numbers help narrow the range, but the procurement decision should still map brightness to room size, ambient light, and content type.

In large-scale commercial projects, buyers should ask: is this for slide-based content in bright rooms, or for video content in controlled light, or for mixed-use spaces where conditions vary?

Resolution, Viewing Distance, and Content Type

Resolution is also context-dependent. A portable projector used for casual viewing may not need the same resolution performance as a fixed-install unit used for fine text, dashboards, or training content.

A practical rule is to tie resolution to the smallest content element that must remain legible at a typical viewing distance. When that requirement is clear, the resolution decision is easier and less subjective.

Throw Ratio, Keystone, and Real Installation Constraints

Throw ratio and placement constraints often drive the success of a deployment more than headline specs. Ultra-short throw and short throw configurations can solve real problems—shadowing, space limits, mounting restrictions—but they also have tighter geometry and alignment expectations.

If your program needs auto-keystone correction, autofocus, obstacle avoidance, or screen alignment features, treat them like functional requirements and validate them under realistic conditions. In large-scale commercial projects, “it works in the demo” does not guarantee “it works in the messy reality of real rooms.”

Connectivity and OS: The Hidden Support Cost

Procurement teams often focus on hardware and ignore the support cost of software and connectivity. But in real deployments, a large share of tickets are not about optics; they are about app behavior, wireless stability, casting performance, or updates.

If you are building an OEM program, confirm what OS options exist, what level of UI/UX customization is possible, and how firmware revisions are managed across production runs. A mature OEM supplier should be able to describe a disciplined process for firmware integration and quality tracking.

DLP Laser Projector Selection: A Procurement Decision Path That Holds Up in RFQs

This is where “education content” becomes “buyer content.” If you want objective traffic that also converts to inquiries, you need a decision path that buyers can reuse internally.

Start With the Deployment Profile, Not the Product List

In large-scale commercial projects, begin with three deployment variables: environment, uptime expectations, and service model.

Environment means ambient light, room size, throw constraints, and surface type. Uptime expectations means daily hours, peak usage patterns, and acceptable downtime. Service model means whether units are maintained centrally, swapped on failure, or serviced onsite.

Once these are defined, the hardware discussion becomes specific. Without them, the discussion stays generic, and generic content rarely drives qualified B2B inquiries.

Translate the Profile Into System Requirements

From our experience in commercial electronics manufacturing, system requirements should include both performance and stability.

Performance includes brightness, resolution, throw ratio, and audio expectations. Stability includes thermal behavior, focus consistency, keystone reliability, connectivity stability, and long-run noise levels.

This is where buyers can add a role signal naturally in the RFQ: “For buyers managing multi-location rollouts, we need consistent behavior across units and production batches, not only single-sample performance.”

Validate Scale Risks Early

Before you scale, validate the items that typically break at scale: mechanical tolerance behaviors, thermal stability under sustained load, and software consistency.

A credible development path includes prototype build, functional testing, burn-in testing, and feedback incorporation before mass production. On Toumei’s services pages, the company describes an OEM/ODM cooperation flow that includes solution design, sampling with functional and burn-in testing, mass production with quality control, and delivery support—exactly the type of structure B2B buyers should look for when they want predictable scale.

OEM/ODM Sourcing: What to Ask a Projector Factory Before You Place a Volume Order

If you want a procurement-ready approach, you need questions that don’t sound like marketing. They should sound like engineering and operations.

Manufacturing Scale and Quality Controls

When a supplier states facility size, output capability, staffing scale, and quality inspection practices, those details matter because they hint at how production is organized and whether QA can keep up with throughput. Toumei positions itself as a professional DLP projector manufacturer based in Shenzhen with OEM/ODM capability, a large production facility footprint, and a quality inspection approach intended to support global B2B clients.

If your program is sensitive—large rollouts, tight deadlines, strict failure-rate targets—ask how inspection is performed, how issues are traced by batch, and what the feedback loop looks like between production and engineering.

Optical Engine, Mainboard, and Software Ownership

From a sourcing standpoint, “ownership” means: who controls the optical engine architecture, who controls the mainboard and firmware, and who can make changes when you need an adjustment.

Toumei describes capabilities that span optical engine development, custom motherboard solutions (from component selection through PCB and firmware integration), and software customization that can extend to UI/UX elements. For OEM buyers, the practical value is that technical changes can be handled within a coordinated system rather than across fragmented vendors.

A Realistic OEM Program Timeline

Procurement teams often underestimate timeline risk. A strong OEM path includes requirement definition, solution design, sample builds, testing, revision cycles, and then controlled mass production. If a supplier can’t clearly describe that flow, the project risk usually rises.

Toumei outlines a six-step OEM/ODM cooperation approach that starts with requirements and solution design, moves through sampling and testing, and then proceeds to mass production and delivery support. That structure is helpful because it sets a shared expectation: a projector program is a process, not a single purchase order.

About Shenzhen Toumei Technology Co., Ltd.

Shenzhen Toumei Technology Co., Ltd. was established in 2013 and is headquartered in Shenzhen, China, positioning itself as an early entrant in the DLP smart projection space. The company describes an integrated model that combines R&D, production, and sales, with a focus on DLP smart projection, 3D imaging solutions, and OEM/ODM projector manufacturing for global customers.

From a buyer’s perspective, the relevant points are operational: Toumei highlights a production setup designed for resource control, cost control, and quality control, along with capabilities across optical design, structural engineering, mold creation, assembly, and testing. It also presents certification coverage and an OEM cooperation workflow intended to support B2B procurement teams who need repeatable development-to-production execution.

If you are evaluating Toumei as a supplier, the most practical next steps are to review the manufacturing and customization scope on the Services page (https://www.toumeipro.com/services/) and to cross-check the current DLP projector lineup for reference configurations and feature sets (https://www.toumeipro.com/dlp-projector-products/).

Conclusion

Laser projectors deliver their value when they’re treated as a system decision, not a single-spec purchase. The reason “laser” performs well in high-use environments is that solid-state illumination can support long operational life, fast on/off behavior, and a maintenance profile that fits commercial realities. But successful deployments still come down to fundamentals: the illumination architecture, optical engine execution, thermal stability, focus and keystone consistency, and disciplined manufacturing controls.

In large-scale commercial projects, the smartest procurement approach is repeatable: define the deployment profile, translate it into system requirements, validate the failure modes that appear at scale, and source through an OEM/ODM process that includes real testing and controlled mass production. For buyers managing multi-location rollouts, that approach turns projector sourcing into a predictable program—not a sequence of surprises.

FAQs

Laser projectors use a solid-state laser-based illumination system rather than a traditional lamp. In commercial deployments, the practical difference is typically longer operational life and reduced dependence on lamp replacements, along with faster on/off behavior. The final image quality still depends on the optical engine, imaging method, and overall system design.

A laser phosphor projector commonly uses a blue laser to excite a phosphor material that produces a broad spectrum of light, which is then processed into image colors. An RGB laser projector uses separate red, green, and blue lasers to generate colors more directly. Each approach has tradeoffs in color performance, optical complexity, cost structure, and scale validation requirements.

Speckle is a known characteristic of coherent laser light interacting with surfaces. Whether it becomes a practical issue depends on the system design, screen or wall material, viewing distance, and ambient conditions. Buyers should validate speckle visibility in the real deployment environment, especially for premium applications or specialty surfaces.

Start with brightness under actual ambient light, then check resolution for text legibility, throw ratio for installation constraints, and the reliability of autofocus and auto-keystone in real rooms. For multi-site programs, also prioritize thermal stability, connectivity reliability, and consistent behavior across production batches.

Request a clear development-to-production plan that includes prototype builds, functional testing, burn-in testing, revision cycles, and controlled mass production with quality control. Also confirm what parts of the system the supplier can customize—optical engine, mainboard/firmware, UI/UX—and how quality tracking is handled across batches for consistent scale performance.